Even pneumatic cylinders know by now that we have specialised in the design and production of standard and customised solutions for over 25 years.

What’s new today, is the introduction of the Rodless Cylinders in the Cy.Pag. Catalogue.

Attention! You will not only find the new cylinders in the catalogue, but all the expertise of each of us, ready to support you in evaluating and choosing the most suitable cylinder for you.

There are in fact some applications that require a linear motion with the smallest possible footprint, for fabric cutting machines for example, or glue application stations.

These applications require the use of the entire available surface area and the pneumatic cylinder with rod does not allow this.

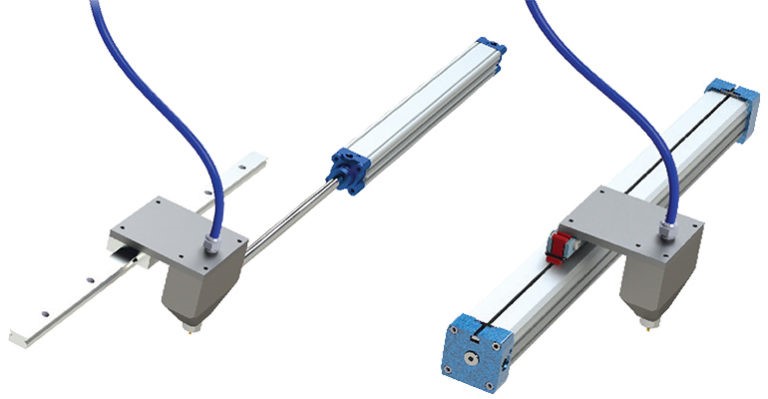

The standard cylinder on the left has the same footprint as the rod, so it needs twice as much space to perform the task as the cylinder on the right.

This constitutes a doubling of productivity for the available surface area.

Why is the Rodless not like a Standard Cylinder?

Let’s be clear from the outset, when approaching a rodless cylinder you need to be very aware of the intended use and its features, which we will discuss later.

This type of cylinder can be like “Messi” for Barcelona, a phenomenon at the disposal of your machine or system, but you have to be very careful about the final use you want to make of this cylinder.

In fact, without a support (internal or external) expert in this type of application, you risk mounting a Ferrari engine on a Fiat Panda chassis, 300km/h potential with a chassis that does not exploit the engine’s strengths.

I am therefore talking about a cylinder with enormous potential, which must be chosen with knowledge of the facts, to avoid mounting it and realising that you have wasted a lot of money on a solution that was not suitable for you.

What is a rodless cylinder

Let’s try to clarify and explain why, how, and when you choose this solution over another.

Rodless cylinders, as the name suggests, do not have a “classic” rod that increases the size of the cylinder when it is in operation, but rather a piston which moves inside the cylinder body. The piston is connected to a loading carriage, which can slide on guides positioned along the length of the cylinder or can slide freely without guides.

This particular operation allows it to have 3 features that make it unique:

About 50% less footprint than a traditional cylinder (when in operation).This feature allows it to be used for long strokes without doubling its size.. In this case, it is ideal for shed doors that open by folding, for a height of 3m, a 6m cylinder will not be required;

Speed;

Smooth motion throughout the stroke, providing greater accuracy. Perfect for example for cutting machines, which require high speed and precision in cutting.

When an application requires one of these features, or a combination of them, then the evaluation of this type of cylinder must be taken into consideration; while keeping in mind other variables that a good technician or salesperson must consider, such as: radial loads, the working environment, the amount of the loads, etc.

Cy.Pag. & Rodless Cylinders

Therefore, one thing will be clear to you by now: before choosing a Rodless Cylinder you must rely on someone within your company who is extremely knowledgeable about this product, or you can contact our sales department, which in synergy with our technical team will be able to provide you with the best solution for your company, evaluating the cost/benefit for you.

This is how we have been working for 25 years and we have learned to sell a service followed by the product and not vice versa as is usual on the market. Last year our customers’ satisfaction was 99.6%, proving that for us (and our customers) this is the right way to go.

For free consultation contact our sales team, who will be able to collect all the information relating to your specific case and, in synergy with our technical department will be able to tell you whether the best solution for you is a rodless cylinder or a customised pneumatic one.

Phone: +39 0342 60 50 11

Email: info@cypag.com