Table of contents

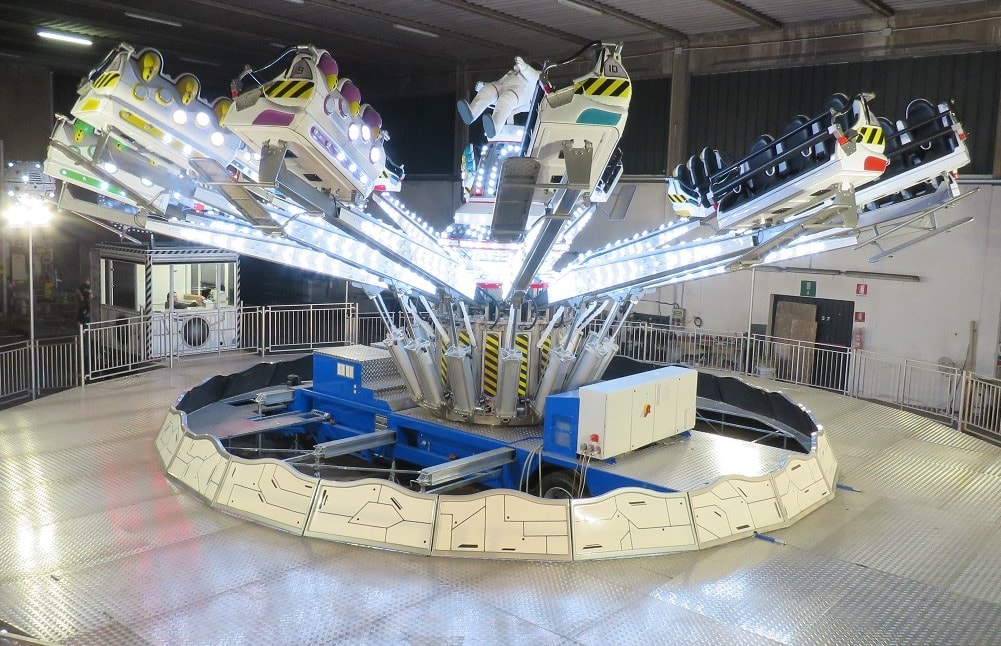

Top Gun accelerations without taking off

Raise your hand, who as a kid has never dreamed of getting on a jet plane and taking off at high speed.

Before you become a Top Gun, you can still experience this feeling on amusement park rides.

We all know how much fun amusement or theme parks are, but only those who design and sell these rides know how difficult it is to strike a balance between fun and safety.

The responsibility for any accident lies with those who design and sell these amusement rides.

No designer or manufacturer of amusement park rides would want to have an accident on their conscience, minor or major that is, that could harm the patrons of the park, like the disastrous failure of a mechanical component in Saint-Germain-en-Laye in 2007, when the nacelle of a carousel broke off, falling into the void and causing the loss of a father and son’s lives, who were 48 and 21.

This is the nightmare that keeps amusement park ride designers up at night.

Even for our designers to sleep soundly, numerous precautions and extensive testing are required so that the (very strict) safety standards of the industry are met.

Some of these tests concern pneumatics, and pneumatic cylinders in particular, which are the muscles that drive the cabins at dizzying accelerations, while guaranteeing maximum safety.

Let’s see together what measures have been taken to build a custom-made cylinder that guarantees to leave passengers breathless (for the sensation of apnea, of course) and puts the minds of the designers as ease about the extreme reliability of the pneumatic cylinder installed.

Where does the need for a custom-made pneumatic cylinder for rides come from?

On adrenaline rides, those that generate high acceleration, with rapid changes of direction, the peak of fun is when you get that feeling of emptiness, of apnea, which gives a rush of adrenaline and creates addiction, because our patrons will want to experience that feeling again, again, again and again.

How do these rides work?

Underneath each arm that supports the nacelle, where the passengers sit, there is a pneumatic cylinder, up to 1m long and with a diameter that can reach 320mm.

These powerful cylinders, when the machine is working, raise and lower the arm of the nacelle with accelerations of up to 4g and speeds up to 4m/s.

Being mounted on a base capable of rotating on the central axis of the machine, we will have both a vertical movement given by the pneumatic cylinders and a rotary movement.

The acceleration achieved generates that famous feeling of emptiness in the belly, which takes your breath away and entertains adults and children alike.

So, one of the key components for the operation of the amusement park ride is the pneumatic cylinder, which with the thrust force of compressed air is able to lift up to 8 tons.

Yes, you got it right, 8,000Kg generated by a piston pushed by compressed air: this is the considerable force that can be released, safely.

To achieve such results and ensure the maximum safety of passengers, however, it is not enough to take a large cylinder, put it in position and start the carousel.

Weeks of design, careful choice of materials and many tests are required to ensure a satisfactory operating speed and product reliability against sudden breakage 100% guaranteed.

But let’s start at the beginning, how did you come to the choice of a custom cylinder?

At the beginning of the 2000s, these rides were mounted large high-speed cylinders: basically, the operation was good, but they had a big problem, because the cylinders requested by the customer literally “ate” the aluminum tube of the cylinder.

Consequently, in order to guarantee maximum safety, it was necessary to replace the pneumatic components, frequently, with increased costs and constant maintenance.

So, the distributor (supplier of the manufacturer of the rides), who then became our partner, started looking for a designer and manufacturer of custom-made cylinders, which would allow him to arrive at a solution with the characteristics listed above, with particular regard, as already mentioned, to the safety and reliability of the product.

The technician who doesn't sleep at night

Designing a custom-made cylinder, on which the lives of adults and children alike depend as they ride the rides, is no small responsibility.

Okay, there are very strict laws on the subject, respecting which our technician should feel relieved, but when it comes to responsibility and human life, precautions are never enough.

That’s why our technicians went to the site to examine the situation, so as to touch the situation with their own hands and assess the problems presented by standard cylinders.

These machines work under considerable stress, with very important loads and not indifferent speeds of movement. When they arrived at the meeting place, they found themselves in front of a cylinder with an aluminum tube and bronze filled PTFE shoe seals.

When the cylinder started working, the bronze pad came into contact with the aluminum tube, wearing the material (both for the high speeds used, and for the choice of a material not suitable to be combined with aluminum tubes), which in a short time presented significant damage due to friction.

The problems did not end here, in fact, the piston not reinforced exposed to very high loads tended to create cracks also very consistent, which meant plenty of sleepless nights for both the designers and owners of the rides.

Safety is paid for, in the maintenance costs which reached exorbitant figures, due to frequent interventions for checks and replacements of pneumatic components.

After a thorough analysis by our technicians of the cylinders they found on site, the response was: a high-speed cylinder that had been adapted to a function far beyond its limits (with inadequate materials) and that required excessive maintenance to compensate for its shortcomings.

What was needed was a custom-made product, specifically designed for this unique application, with uncommon strength and reliability characteristics: with a speed of 4m/s and an acceleration of up to 4G, against the maximum speed of a standard cylinder of about 1m/s.

These were the prerequisites to start the design of a tailor-made cylinder, with high strength materials and correct sizing to ensure maximum reliability.

The Cylinder that flies safely, without taking off

A design of this kind becomes even more complex because of the strict legal standards on safety, which must combine fun and reliability of the carousel, so as not to end up in the news of local and national newspapers.

Right from the start, the choice of materials played a fundamental role.

In fact, for this special application, it was decided to keep the aluminum tube and replace the bronze filled PTFE with graphite filled PTFE.

It took a few months between design and making of the prototypes stage (cylinders ø250 and ø320), which sometimes upset the dreams of our fearless designers, who finally pulled the rabbit out of the hat, that is a cylinder tailored for rides.

However, people’s lives were not at stake, which is why extremely scrupulous tests followed, which had to confirm the safety and reliability of the customized pneumatic solution.

Long and laborious tests on the test bench, under conditions of prolonged stress, to ensure durability, resistance to stress, but above all fun in safety, which is the essential characteristic of this type of machine.

Once the test phase was passed, they were finally mounted on a working carousel.

Today our cylinders entertain and “fly” safely thousands of people a year.

Safety and Maintenance Made to Measure

After years of uninterrupted use and a collaboration, we can affirm that the cylinder that was designed has allowed our customers to sleep soundly. In fact, over the years, there have never been any accidents or breakages.

Let’s face it, even though safety is a minimum requirement in this sector, you can’t take anything for granted, and crime news teaches us that sometimes it doesn’t take much for something to go wrong.

Our custom cylinder has stood the test of time and has again shown that such a cylinder is vastly superior to its standard counterpart.

So, what were the concrete benefits we brought to the customer:

- The greater mechanical resistance brought by the new product made it possible to reduce the frequency of maintenance work, thus reducing this type of cost;

- A highly specialized technical department, able to provide support for any need, 365 days a year;

- The versatility of Cy.Pag., specialized in the management of custom cylinders, has allowed us to adapt these solutions for a multitude of different rides; in some cases even pre-existing ones with dedicated projects for each single machine in order to extend the benefits obtained to all the customer’s production.

Thanks to these projects a solid collaboration between Cy.Pag. and the customer has been created, a synergy that has lasted for almost 20 years.

The measures that have been taken have allowed the company to guarantee itself a long-lasting competitive advantage on the market.

All this has been possible because the company has outsourced the design of a very particular component to a company specialized in this niche market.

Our designers have been able to do this project thanks to their in-depth and specific technical knowledge, also quite innovative, which they have developed with more than 5,000 tailor-made realizations and millions of pieces sold.

Cy.Pag. has a well-tested system of development, which allows us to understand the needs of the manufacturer, even the most particular, specific for each application sector.

For more than 25 years, in fact, we have been designing custom-made pneumatic cylinders for various industrial sectors, which have different characteristics and obviously different needs.

To request a free, exploratory consultation to evaluate a custom pneumatic solution, contact us at +39 0342 60 50 11 or email us at info@cypag.com.