NASA itself uses it for its own safety devices because the high precision and reliability make it the perfect tool to guarantee maximum results in total safety.

In fact, this cylinder is:

- STURDY, because built in one piece, which guarantees high precision work without vibrations (or vibrations reduced to a minimum)

- POWERFUL, because it is able to support heavy weights, so that your machines will have superior performance

- HIGHLY ACCURATE, because it is guided in movements

- PERFECT as a stopper thanks to the resistance to lateral stress

- RELIABLE thanks to its compactness

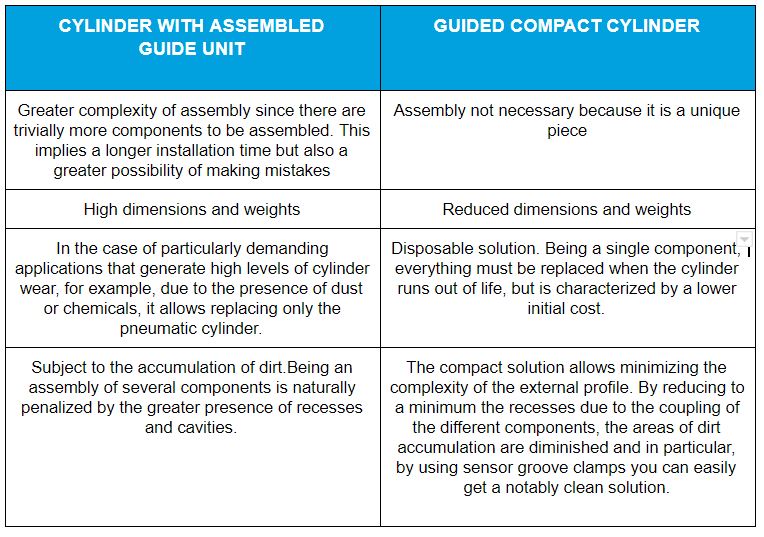

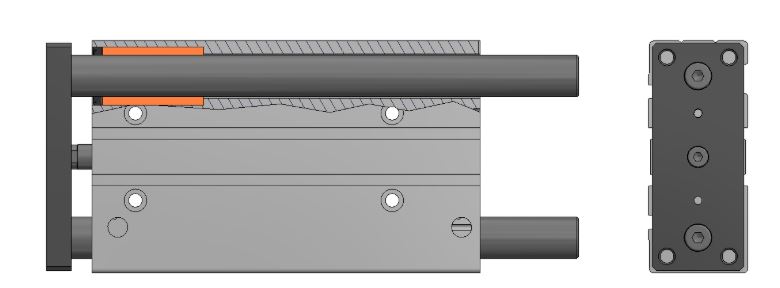

Typically, the compact guided cylinder is composed of an extruded profile in which a central chamber with pneumatic function and lateral channels for housing the guide rods are obtained.

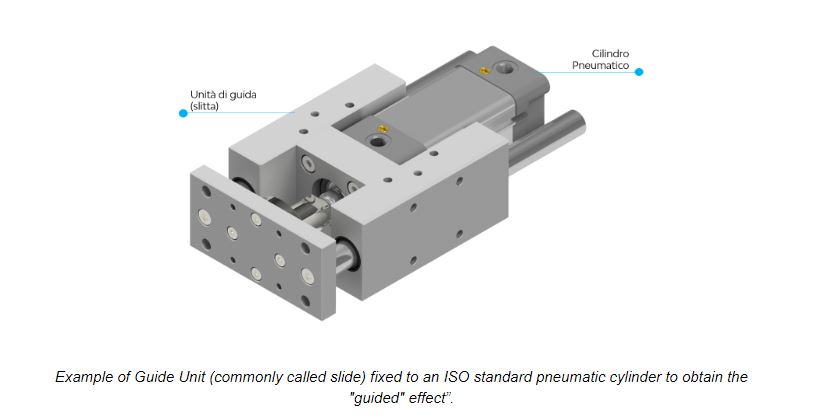

The compact guided cylinder performs a function equivalent to the version consisting of a pneumatic cylinder with a mounted guide unit, but the compact solution continues to be the most adapted for carrying heavy loads.

The equivalent type of arrangement is achieved with the compact guided cylinders which are, however, characterized by a compact and non-separable monoblock body.

Example of a guided compact cylinder

Example of a guided compact cylinder

The only drawback, of which we are aware, related to the guided compact cylinder, is that at the end of its life, you have to replace the entire single body because its high reliability is guaranteed by the compact construction.

But it is equally clear that if on the one hand, it allows you to replace the cylinders at the end of their useful life without having to change the guide unit, on the other, it forces you to make the latter from a full block with a clear disadvantage in terms of costs.

In this case, however, the initial cost will be significantly lower than that of an ISO cylinder with guide unit, hence the compact version always remains the most convenient one.

What are the differences that can help me choose between a cylinder with a guide unit compared to a compact guided one?

In the table below we summarize the main indications, the advantages and disadvantages of the two solutions

It is easy to think of the guided compact when we see a cylinder with two rods, but it is important to make some clarifications to identify the two versions.

When a cylinder has two or more rods side by side, it is naturally equipped with an anti-rotation function but it is not necessarily equipped with an increased guide.

As an example, we can mention the Twin Rods cylinders which perform the anti-rotation function very well but are not designed as cylinders capable of supporting particularly high lateral loads and have guide bushings substantially comparable to those of normal single rod cylinders.

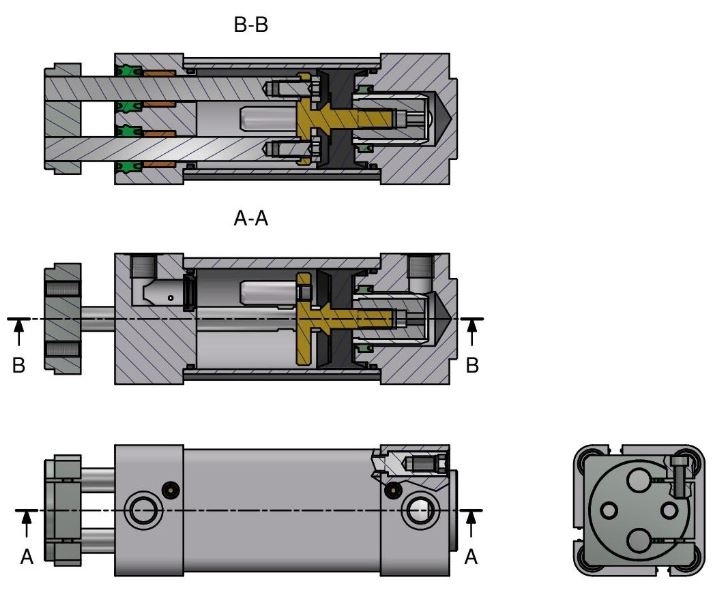

A further example is that of compact anti-rotation cylinders.

In this case, the cylinder is equipped with real guide rods, i.e. rods designed with the sole function of guiding the main rod of the cylinder.

In this case, the cylinder is designed as an interchangeable version, in terms of dimensions, of the single rod cylinder. Consequently, the dimensions of the guides are considerably limited by the dimensions of the standard cylinder.

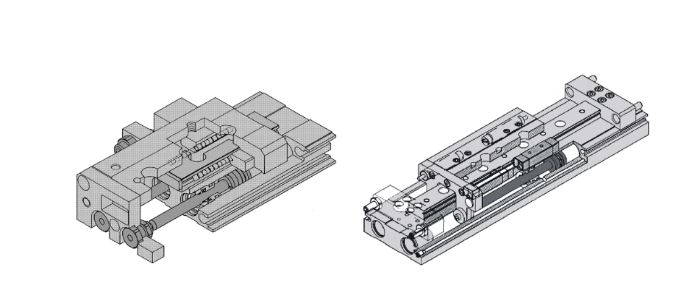

Example of anti-rotation compact cylinder

Example of anti-rotation compact cylinder

Compact Guided Cylinders are cylinders primarily designed for their resistance to movement and lateral loads.

In this case, the dimensions of the rods and guide bearings are not limited by other requirements and are sized in such a way as to guarantee a considerable driving effect.

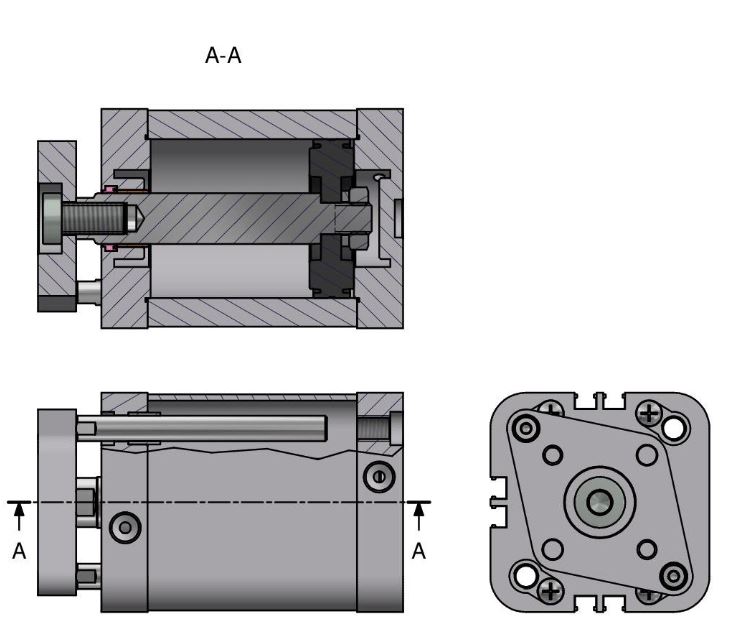

On the market there are various other types of cylinders equipped with guides, such as for example cylinders with lateral sliding table, with and without rod, in an “L” shape, etc.

Example of Cylinder with precision slide and with long stroke precision slide.

Example of Cylinder with precision slide and with long stroke precision slide.

The guided compact cylinder must be taken into consideration when we want to achieve a sufficiently precise movement in the presence of lateral loads or heavy torsion.

However, it does not have the resistance to loads of the actual guide units, nor the accuracy in the order of hundredths of the sliding tables.

In this sense, the guided compact is a choice that we must consider when we want a solution that is easy to use and install, compact and economic, capable of creating a movement without the need for additional guides or supports.

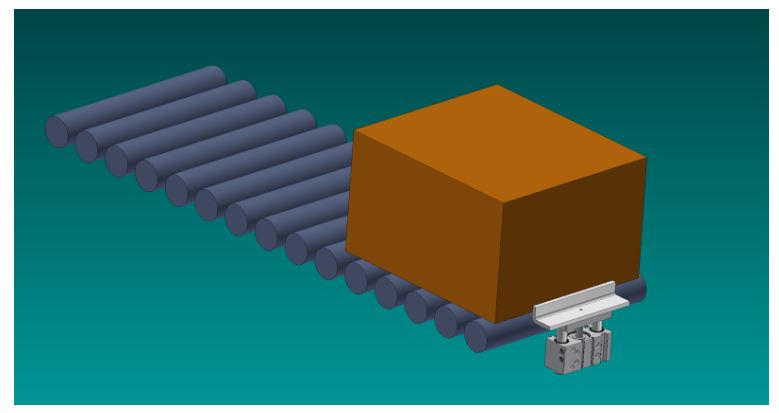

The guided compact cylinder is found mainly in the pick & place, logistics and automation lines because they are particularly suitable for …

- Carrying weights

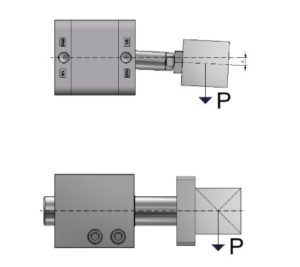

The guided cylinder is capable of autonomously supporting weights, also directed transversely to the rod, while remaining correctly aligned.

Compared to a traditional cylinder, the bending of the rod following the application of lateral loads is significantly less.

- Working as a stopper within automatic lines

This is the case of lines or machines equipped with conveyors.

The compact guided cylinder, thanks to its resistance to lateral stress, performs very well the function of stopper even for components with heavyweights.

- Suitable for positioning operations

The high precision makes it ideal for building even complex movements using 2 or more cylinders in combination. It is particularly suitable for positioning operations thanks to the high repeatability and precision of the end positions.

I’ll explain what you don’t have to give up when buying a guided compact cylinder to keep your production precise and fast.

A compact cylinder guided thanks to the alignment guaranteed by the guide rods and the bearings, whether they are sliding or recirculating balls, must guarantee smooth movement, without jerking and vibrations.

Sliding bushings and ball bushings

Rod guide bearings are the key components of this variety of cylinders. In general, they have the function of supporting and guiding the components in relative motion and consequently they transfer the forces applied on the rods to the cylinder body.

These are therefore the components that allow obtaining the high standards of precision in movement, characteristic of this type of cylinder.

Quality bearings, whether they are plain bearings or ball bushings, must perform this function by limiting friction and consequently noise, heating effects and above all wear.

Quality bearings, combined with precision rods, drawn and ground, allow to obtain high performance and long useful life.

But what is the difference between the plain bearing and the ball bushings?

The sliding bushings made with high precision lathes starting from bronze bars allow obtaining reduced friction coefficients while keeping the front section to a minimum. This makes it possible to use guide rods of considerable size also for the smaller bore cylinders and in general, allows to support high loads both of the static type and in the form of shocks.

For example, therefore they will be more suitable for stopper-type applications.

The ball bushings, unlike the sliding bushes, place steel balls between the surfaces in relative motion. This means that the friction between the parts is of the rolling type and not of the sliding type.

The advantage of this type of solution is inherent in this difference since the rolling friction is considerably less than the sliding friction.

Consequently, the cylinders with ball bushings are particularly suitable when a more fluid movement of the cylinder is necessary or in any case appreciable.

For example, therefore, they will be preferable for cylinders that perform lifting or translation.

Straightened Front Plate

One of the fundamental aspects to keep in mind when choosing a compact drive is the quality of the front plate. A perfectly constructed and aligned cylinder would be useless without proper fixing. A not perfectly planar front plate, in particular, would nullify the efforts made to perfectly align the guides to the direction of motion. In this sense, therefore, it is fundamental that a guided cylinder is provided with a straightened plate to guarantee maximum flatness and correct alignment up to the user…

Version with self-cushioning system

Pneumatic cylinders can reach very high speeds which can create high-intensity impact forces at the end of the stroke.

In these cases, to avoid damage to the cylinder structure and/or the connected mechanisms, the energy generated by the load during movement must be reduced or canceled before the piston reaches the end position.

The self-cushioning compact guided cylinders automatically decelerate by diverting the exhaust air in a passage divided by an externally adjustable valve. This allows to reduce the impact speed and therefore the impact as well as the generated noise.

High resistance polyurethane gaskets.

For all the dynamic seals, i.e. the seals of the piston rods and those of the piston, except in the case of specific needs, such as high-temperature operation, it is advisable that they are of high quality and made of polyurethane.

The polyurethane gaskets guarantee, in fact, a high mechanical and wear resistance. The use of greases with PTFE then elevates their performance by reducing friction and therefore the effects of wear.

Now that you know what the optimal characteristics of a compact guided cylinder are, I recommend that you never, ever forget to require the best from your component suppliers and apply every installation suggestion and recommendation to the letter.

Team Marketing Cy.Pag.

PS: If you have questions, doubts or need the help of any kind to improve the performance of your machines, we are here to offer you the best possible experience.

If needed, write to info@cypag.com and a tutor will help you with all the information you need to make your experience with us remarkable.