Industry 4.0

We help companies and machine builders to increase the efficiency of compressed air use, saving money and improving production

Who is this project for?

- Companies equipped with a compressor room for the operation of production machines

- To machine builders with pneumatic systems that aim to differentiate themselves by offering innovative products to their customers

Do you use Compressed Air Machines?

If you are an End User...

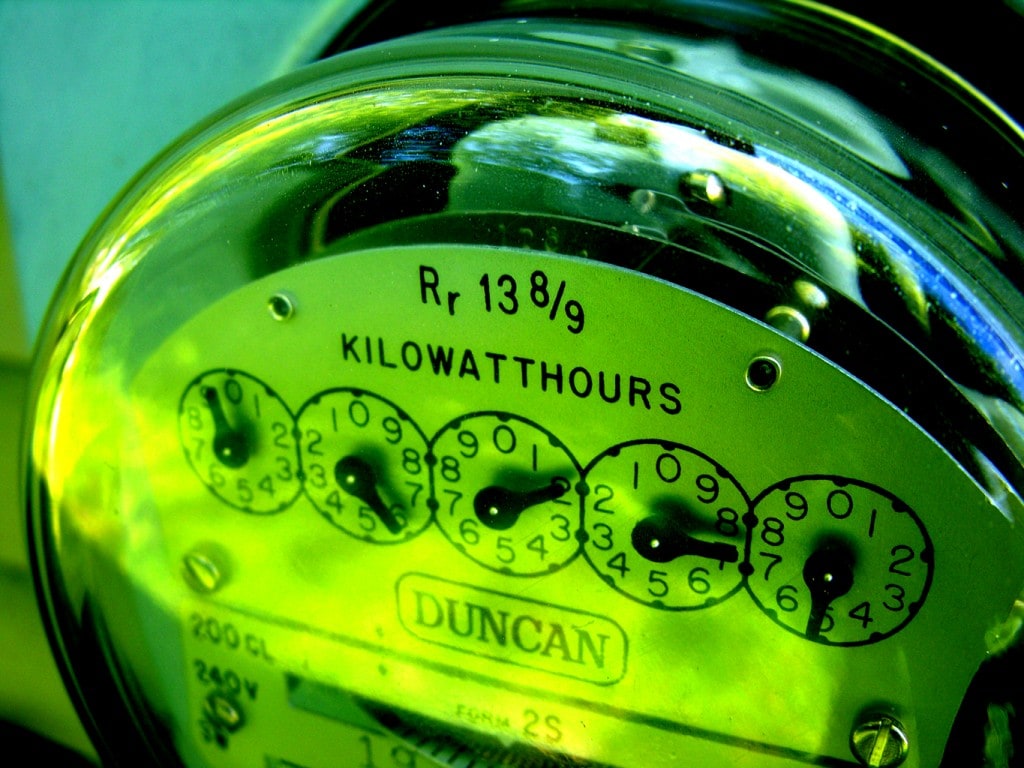

How much does misinformation cost in energy waste?

Today in Europe’s industries, electricity consumption is estimated at around 1,013 TWh/year, 20% of this expenditure is for compressed air production.

However, 30% of the compressed air produced is dispersed in losses.

Basically 9 billion euros are spent in Europe every year for nothing.

This means that only by eliminating the losses related to compressed air in your network, you take home 6% of the electricity bill.

Leakage remediation, however, is only part of what you can do. There are several technologies at your disposal, some of them with a very high degree of innovation. To know which of these technologies you can use, you must first make a diagnosis.

This analysis will allow you to make decisions whose consequences could be:

- Significantly increase your production rate

- Save money on your electricity bill every month

- Decrease the environmental impact of your company

- Know what is about to break, what needs maintenance and what needs to be replaced to avoid downtime

- Monitor and analyze your consumption ... from the beach.

Analysis

To understand your situation and adopt the most effective strategies, we start with a series of questions:

- How much compressed air is produced in the compressor room? Alternatively how much is purchased?

- How much does compressed air cost?

- How is it used?

- How much of the produced or purchased air is dispersed in losses?

It is essential to define the amount of compressed air produced

To determinate the cost expressed in euro/pcs or the annual cost of the compressed air carrier.

Optimization

Following consumption analysis and leakage remediation it is possible to gradually choose where and how to optimize compressed air consumption using the most suitable technologies.

Compressed Air Flow Optimization

Replacing the function performed by compressed air with other solutions

Do you build compressed air machines?

If you are a Machine Builder...

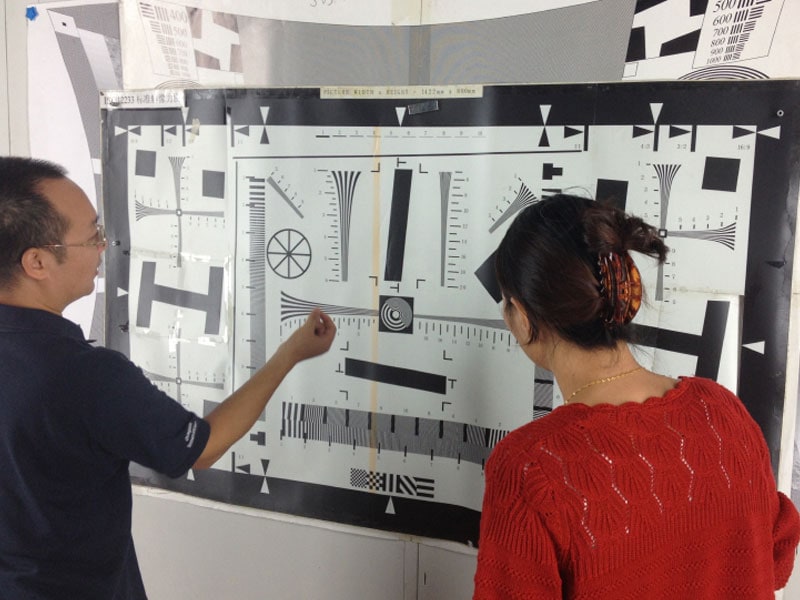

The machines that are required by the industry today can be much more straemlined and efficient thanks to a correct and advanced integration of pneumatic components.

Today the trend of machine designers is to rely on standard pneumatic solutions able to guarantee the required mechanical movements, without knowing that more effective and in some cases even cheaper cylinders can be used.

How to calculate the energy consumption of the cylinder drive and why is it important?

To understand how to reduce energy consumption in the compressed air industry it is necessary to understand the principle of compressed air work. Thermodynamic principles are necessary to determine the energy consumption and, therefore, the energy saving potential of pneumatic drives.

Here’s how to optimize your machinery:

- Design

- Cylinder dimensions

- Cylinder applications

- Supply pressure adjustment

Engineering Support

Our Involvement

Starting from the strategic phase, it will contribute to redesigning the processes according to a new logic.

Use resources more effectively

Eliminating unnecessary maintenance activities

Overall Improvement

Eliminating unnecessary maintenance activities

Calculate your

Potential Saving

Use the free online tool to calculate your potential savings.

Select the parameters of your system, the life cycle and cost calculation to get an assessment of the various energy saving indicators applied to your company.

4.0 INDUSTRY services have the principle of reducing compressed air consumption and increasing the use of the components involved.

Companies are constantly looking for innovative products. With the Industry 4.0 project, Cypag wants to help you optimize the compressed air carrier and to design machines that consume less, equipped with control systems that warn the operator when malfunctions occur.

Energy Efficiency

We perform, in a very short time, a real pneumatic audit of a machinery or of an entire production line, to identify sources and components that cause energy waste. We track down the best opportunities for performance improvement and empower them to achieve measurable, fast and sustainable results.

Predictive Maintenance

The products and services are predisposed to the Modbus cloud model (communication protocol widely used in the industrial sector). This allows us to diagnose in advance any critical issues and failures (economic, environmental and safety) by monitoring significant parameters, measured and profiled according to appropriate mathematical models. We wisely save these data to be able to implement preventive actions.

Engineering Support

Our involvement from the strategic phase will contribute to redesigning the processes according to a new logic. We can now rethink resources effectively, eliminating unnecessary maintenance activities and improving overall production efficiency. We make sure that the skills we leave behind are as valuable as the productivity improvements we help create.

5 steps to improve your business

The Most Innovative Products On The Market

PNEUMO AUDIT

Cy4.0 SMART CONTROLLER

BLOWAIR

PICKSAVE

SHERLOCKAIR

MICROLEAK

What Customers say...

Find out how Cypag can save you up to 30%

Click on this button and leave your details to receive a free consultation in order to:

- Reduce the waste of compressed air

- Take advantage of unique and innovative products still little known in the pneumatic market

- Obtain professional maintenance by specialized figures in the pneumatic field

- Remotely monitor the operation of the machine, monitor its data and know in advance any anomalies